RAM OIL 280

INDUSTRIAL VACUUM

Sump Vacuum Cleaners For Oil And Chips

The RAM OIL 280 industrial vacuum, with its 280 liters tank, is widely used in cleaning the tanks of CNC machines, thanks to its cleaning speed and the speed with which they replenish the oil lubricants-coolants in the tanks and vacuum metal shavings and swarf. The RAM OIL 280 industrial vacuum from the Depureco oil and swarf range uses the “reverse flow” system to empty liquids. This system eliminates any additional maintenance and risks arising from the pumps clogging when transferring liquids. Professional suction is generated by a side channel blower that ensures an excellent vacuum speed and refill of liquids. The vacuum cleaner tank contains a quick-release metal basket that is used to separate the solid part from the liquid part. The 150-micron filter ensures a more effective filtration on the swarf. The electrical level indicator inside the container stops the airflow upon reaching maximum capacity. The vacuum is supplied as standard with the perfect oil accessories kit for vacuuming CNC machines. A drainage pump can be supplied on demand and fitted for the continuous discharge of liquids.

Highlights

SUCTION UNIT

The suction unit is a side channel blower with direct coupling between motor and impeller. The side channel blower is equipped with a safety valve to guarantee continued work in complete safety, without any maintenance. The blower is also equipped with a metal silencer to maintain a low noise level.

INLET

The vacuumed material enters the machine through a flanged intake nozzle located above the metal mesh basket's lid to then be filtered inside it. The quick release basket is equipped with a PPL filter and acts as a sieve. The liquid is then collected inside the large tank, ready for re-use.

FILTERING ELEMENT

The collected liquid goes through a PPL filter with a 150µ efficiency. Thanks to it it's possible to separate even the smallest solid particles, making the filtered liquid suitable for reuse. The filter can be washed and reused easily. A disposable TNT filter (efficiency 100µ) is also available.

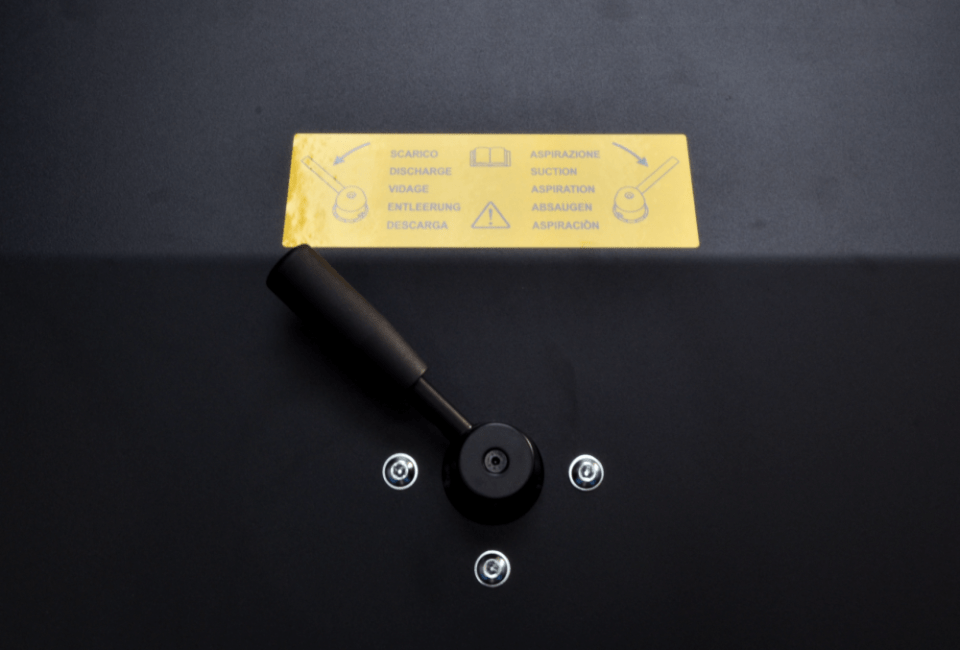

DISCHARGE SYSTEM

Using the inversion of the blower's outlet airflow, which can be activated through a handy ergonomic lever placed on the pump's casing, the vacuumed liquid can easily be discharged. A tap placed on the rear part of the machine enables the operator to attach a hose for discharge and to control the outlet flow.

Technical data

Motor

| Type | side channel blower |

| Voltage | 400 V |

| IP | 55 |

| Vacuum in continuous run | 220 mBar |

| Maximum air flow | 220 m3/h |

| Safety valve | included |

| Noise level | 72 dB(A) |

| Frequency | 50/60 Hz |

| Power | 3 HP |

| Insulation class | F |

| Suction time | 280/80 |

Machine

| Suction inlet | 50 Ø mm |

| Dimensions | 700 x 1450 mm |

| Height | 1400 mm |

| Weight | 220 Kg |

| Liquids capacity | 280 |

| Solids capacity | 40 |

| Type of discharge | inversione di flusso |

| Discharge time | 280/80 |

Options

STRUCTURE AND OPTIONS

BX

Stainless steel bin AISI 304

PUMP

Continuous discharge pump

Submerged pump for continuous discharge

Gallery

Resources

Request free quote

Caricamento …